Let’s look at another misconception about dehumidification that is akin to controlling to relative humidity (RH). Perhaps you’ve heard that adding reheat to a rooftop unit (RTU) is another means of dehumidification.

This is a fallacy, and here’s why.

Understanding that RH drops when air is heated, it is easy to see why one might think (incorrectly) that heating the air, or reheat, is part of the moisture removal process. It is not.

Reheat

In order to understand the two ideas and the differences between them, we need to get a little technical and refer to psychrometrics (the study of the physical and thermodynamic properties of gas-vapor mixtures, most commonly moist air).

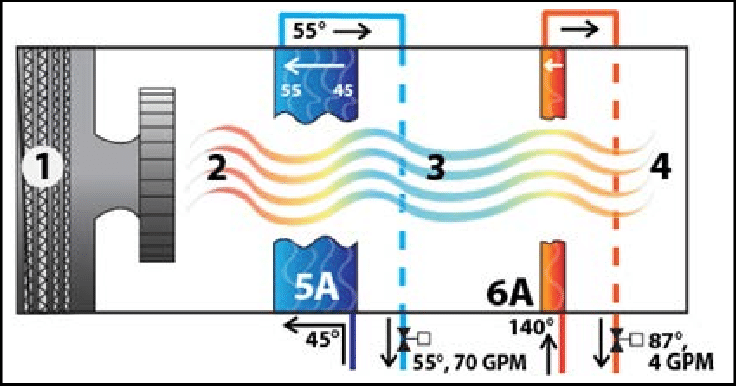

Let’s say we cool some air to the saturation point – the temperature at which the air cannot hold more moisture. This is the point water begins to condense out of the air. The amount of cooling required to remove moisture from the air results in colder-than-desired air. This is where reheat can play a role.

Reheat is ‘free’ heat taken from the running unit’s own compressors. The reheat coil is placed after the cooling coil to temper the air back to a more comfortable level.

As an aside, this explanation does not include Flō’s truly amazing adaptive multi-path technology that mixes the airstreams to get both free cooling and heated air in dehumidification mode.

For this purpose, we’re focusing on reheat alone. It is only for adding heat, not removing moisture.

There is certainly more to cover about why using a standard RTU for reheat and attempting to dehumidify the air is not a good idea (for example, coils are typically not designed to provide enough capacity for dehumidification), but we’ll leave this topic for another blog post.

Heat Reclaim

Heat reclaim provides unique benefits to food retailers because of the presence of refrigeration racks. In the food retail environment, heat reclaim is the process of capturing already-paid-for heat from the refrigeration rack, which would otherwise be expelled to the outside air.

When available, this is a real game changer, particularly with decarbonization and electrification strategies. We use heat reclaim over reheat whenever possible. Like reheat, heat reclaim is not part of the moisture removal process. It is exclusively used for heating the air and has nothing to do with dehumidification.

When comparing the two, heat reclaim does so much more! Reheat is heat from our own unit’s compressors, which means they must be running in dehumidification mode to be able to harness that heat. Reheat is limited in scope and application.

Heat reclaim, on the other hand, captures waste heat from the refrigeration rack and can be used any time. Heat reclaim is another benefit of using our Flō units with our Adaptive Multi-Path technology.

Here’s Where the Magic Happens

An important part of Flō’s strategy is that we use heat reclaim (glycol, refrigerant or CO2) as the first stage of heat. Why? Because we want our customers to save on heating bills. The heat is already paid for! The more heat we can get from the rack, the more your stores benefit. This is why CO2 is so beneficial; it operates at higher pressures and temperatures compared to other refrigerants. It works so well that, in many cases, we can heat the entire store utilizing reclaim alone. Imagine what this does for your electrification goals!

CO2 heat reclaim is not a new concept. Flō will very soon pass one thousand installations of our DOAS+ units with Adaptive Multi-Path technology with CO2 heat reclaim. To my knowledge, there is no close second.

Even still, we have exciting new innovations coming that benefit the refrigeration rack — leading to even deeper energy savings. There is so much rich content to cover here, but we’ll leave that for another blog as well.

Until next time, remember …

Control to dew point for dehumidification and use CO2 heat reclaim to heat your stores.

Author: Barb Zyskowski, P.Eng. is Vice President of Sales at Flō Energy Solutions.

Flō Energy Solutions has worked exclusively in food retail for 25 years. Check out our website to learn more about how we partner with food retailers to create an optimal balance of energy use, moisture control, mechanical systems integration, and store comfort.